Raise your Query

Hi! Simply click below and type your query.

Our experts will reply you very soon.

Hi! Simply click below and type your query.

Our experts will reply you very soon.

16, Prince Apartments, Chinna Waltair, Kirlampudi Layout, Waltair, Visakhapatnam, Andhra Pradesh - 530017, India

Call Us : View Mobile Number

E-mail : srinivas@firstesco.in

|

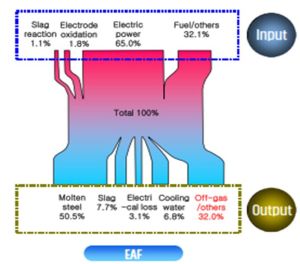

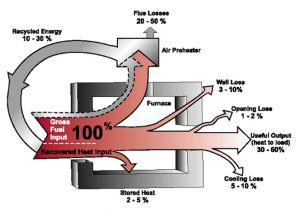

Steel industry is energy intensive, requiring large amount of electrical energy as well as heat energy through use of fossil fuels. In most of the furnaces used in the steel making process, some amount of heat energy will be lost to the atmosphere through flue gases. Typically, 20-25% of the input energy is lost through read more... |

|

Glass kilns utilise heavy fuel oil (HFO) or natural gas. Typically a glass furnace exhaust flue gas will be at a temperature of 450-500°C. As per available statistics, the energy lost through exhaust flue gas will be in the range of 25-30% of input energy. For a seven hundred ton capacity glass furnace, the energy lost read more... |

|

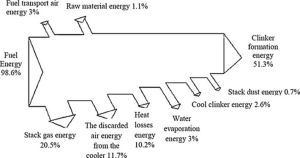

Cement manufacturing is an energy intensive process. By improving the energy efficiency in terms of thermal and electric energy, it is possible to improve the bottomline by cost optimisation. In a cement kiln, 22.5% energy input is lost to the atmosphere through flue gases. By recovering the thermal energy available in the read more... |

|

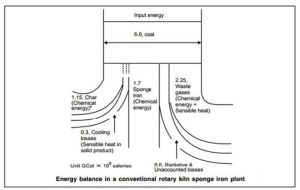

Sponge iron kilns are energy intensive. 30% of the energy input to the kiln is lost to the atmosphere through flue gas. Many sponge iron plants with kiln capacity higher than 200 tons, the heat in the exhaust flue gas is already utilised to generate steam and generate power. However, sponge iron plants with a capacity less read more... |